Milling and Turning Capabilities

Advanced Milling Operations

Our horizontal CNC machining centers provide superior rigidity and precision for complex milling operations. Twin-pallet systems ensure continuous production while parts are loaded and unloaded, maximizing spindle utilization and helping economize on per-part costs. Tombstone fixtures accommodate up to 6-8 pieces simultaneously, optimizing cycle times for medium to high-volume production runs to facilitate swift delivery.

Key milling capabilities include:

Multi-axis milling

Complex geometries and challenging features machined in single setups

Heavy-duty operations

Cast iron and steel components requiring aggressive cutting parameters

Precision boring

Tight-tolerance for creating precise holes with smooth interior surface finishes

Custom fixturing

Engineered workholding solutions for complex part geometries

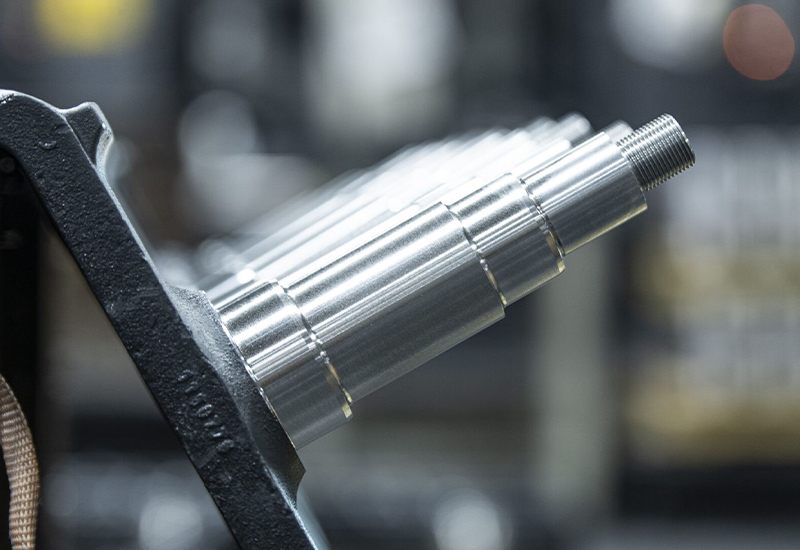

Turning and Boring Capabilities

Our variety of lathes and boring mills handle components from small precision parts to large industrial housings. Whether your application requires straightforward turning operations or complex boring and facing work, our equipment lineup provides the flexibility to meet diverse manufacturing requirements.

Turning capabilities encompass:

Precision turning

Tight diameter tolerances and superior surface finishes

Heavy-duty boring

Large diameter holes in cast iron and steel components

Complex geometries

Multi-feature parts machined complete in single setups

Production volumes

Optimized for 500+ pieces per month

Materials and Applications

Our milling and turning operations excel with challenging materials including cast iron, ductile iron, steel, stainless steel and aluminum. Cast iron machining represents a particular specialty. We maintain dedicated equipment setups that deliver consistent results while managing tool wear and coolant systems effectively. We also apply specific boring strategies to help maintain the desired surface finishes on challenging materials.

Integrated Quality Systems

Every milled and turned component undergoes rigorous quality control including dimensional inspection, surface finish verification and traceability. Coordinate measuring machine (CMM) capabilities, first article inspections and 100%-part inspection help ensure that components meet our customers’ exact specifications prior to shipment.

Companies that require durable, heavy-duty components that can slip smoothly into a just-in-time operations schedule trust Barth Industries’ milling and turning capabilities to provide the precision and reliability that keeps production lines humming.

Equipment

An assembly of advanced equipment is at the heart of Barth Industries’ precision manufacturing capabilities.

View EquipmentMarkets Served

Barth Industries can supply precision cast iron and steel machining solutions across diverse industrial sectors, from transportation equipment to heavy machinery and emerging sectors like electric vehicles.

View MarketsQuality Matters

Precision manufacturing at Barth demands unwavering quality standards at every stage of production.

More on Quality